FCM

Automated Fuel Consumption Metering and Ship Efficiency Monitoring System

THE WAY TO SAVE AND REDUCE EMISSIONS!

FCM SYSTEMS - An universal tool that allows the crew and operators of vessels to easily and automatically control bunkering, fuel consumption by the ship and its fuel level in tanks. Our systems are designed both for monitoring the efficiency of the vessel as a whole, and for automatically collecting the necessary data on fuel consumption for the preparation of MRV reporting. The purpose of this development is to make the work of a shipping company more efficient and to simplify the work of all its services.

Our solution allows you to identify increased fuel and energy consumption on board, as well as control CO2 emissions

This is a comprehensive solution that helps the shipowner to solve problems aimed at meeting the requirements of the IMO. In particular, the collection of information for the maintenance and transmission of MRV reporting and data for SEEMP. Solving these problems, our product additionally provides the shipowner with many useful functions.

AUTOMATION OF DATA EXCHANGE WITH EU-MRV AND SEEMP SYSTEMS

EU-MRV reporting is essential for the shipping industry to monitor greenhouse gas emissions.

The reduction can be achieved with the help of technical and operational adjustments to the operation of ship systems and mechanisms.

SEEMP (Ship Energy Efficiency Management Plan)

One of the most promising instruments for the shipowner to improve the energy efficiency of ship operation is SEEMP.

One area for SEEMP improvement is fuel efficiency

Our systems help build EEXI

(Energy Efficiency Existing Ship Index)

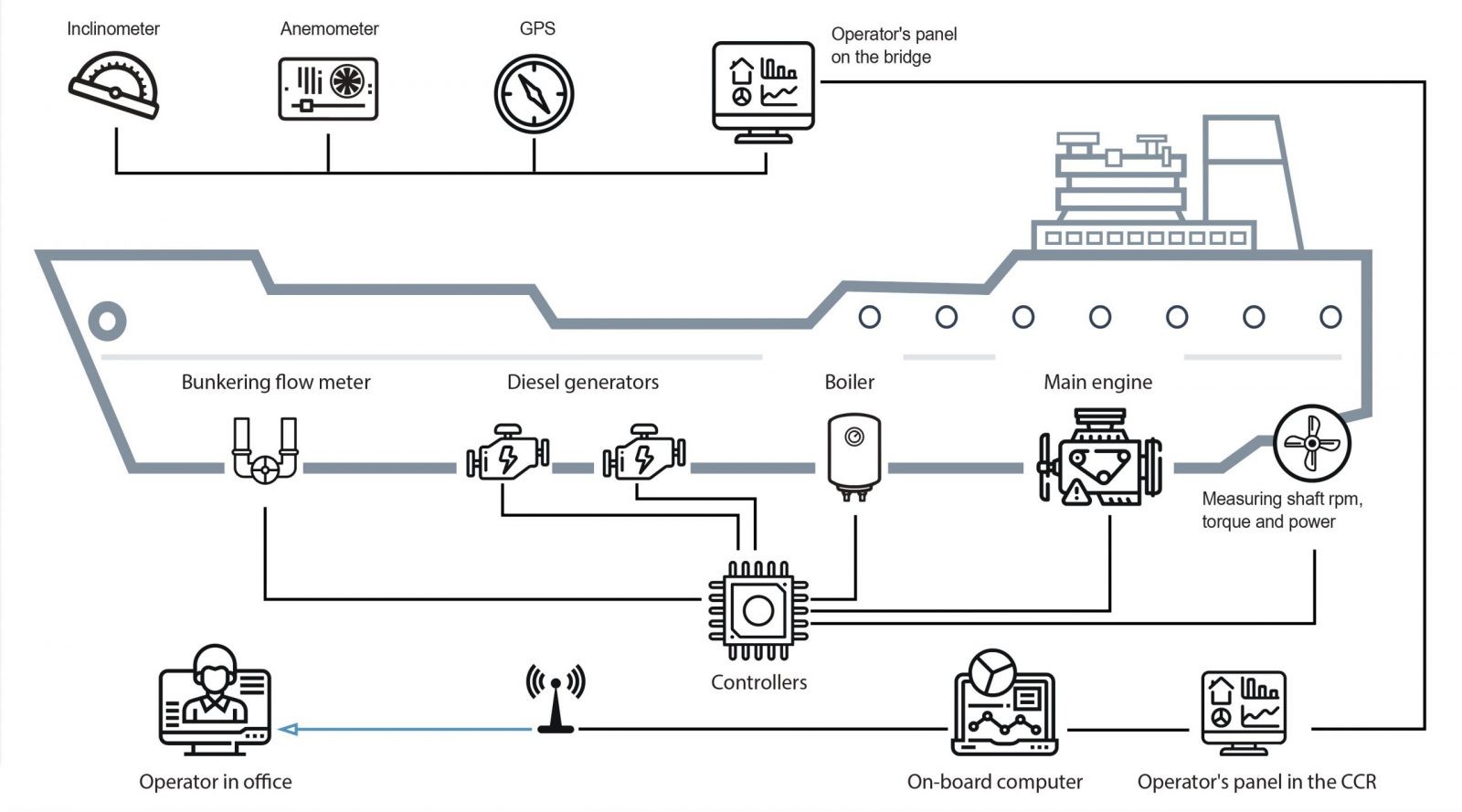

Monitoring the amount of CO2 exhaust gases, comparing with fuel consumption, processing and transmitting data to the office.

- Main engines

- Diesel Generators

- Boilers

- Bunkering line

- Propeller shaft

- Inclinometer

- Anemometer

- Viscometer

- GPS

- Database

Additional functions

- CO2 exhaust gas monitoring

- Boiler, pump and valve control

- Fuel level control in tanks

ADVANTAGES OF THE SYSTEM FOR SHIP OWNERS

Turnkey projects from inspection and design to installation and follow-up

Possibility of phased commissioning of the control system, depending on the requirements and budget of the client. At the same time, ensuring the excellent functioning of each module put into operation.

Monitoring the dependence of nitrogen oxide emissions on consumption: MARPOL 73/78, resolution MEPC. 217 (63)

The ability to analyze readings in instant mode and over a period of time

Flexible software solutions developed by our programmers

Measuring equipment with all marine approvals and certificates

Monitoring the dependence of fuel consumption on the operating modes of a single complex of equipment (on speed, power, number of energy consumers, NOx, SOx and CO2 emissions, the possibility of installing pumps for dosing fuel additives)

User-friendly graphical perception of information (graph design and compatibility with standard operating systems)

Compatibility with existing equipment with automatic process control systems

Bunkering equipment with OIML R117-1 certificates for HFO, MD0, and MGO;

Automatic protection of equipment (minimizing the “human factor”)

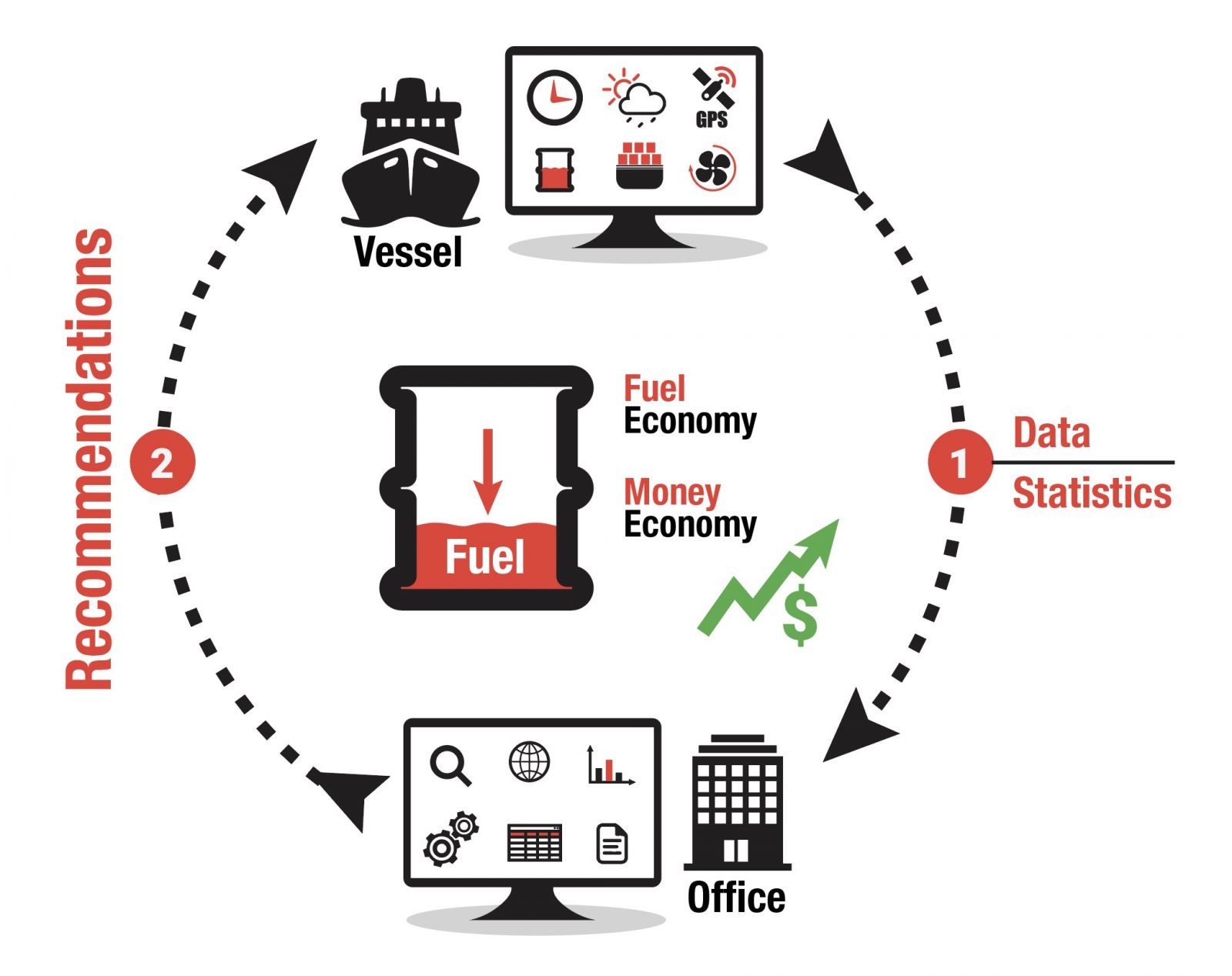

Automatic data transfer to the central office

FCM system concept

Modularity

FCM System is modular, it is developed individually for each vessel / project.

MODULAR SOLUTION IS:

- saving money and time

- use of existing equipment

- system expandability

- replacement of modules in the shortest possible time

WORKING PROCESS / FULL PRODUCTION CYCLE

Planning

Based on the request, a project action plan is drawn up

Design

The necessary equipment is determined, on the basis of which a price offer is drawn up

System assembly

The user interface is created and the necessary equipment is assembled

Mounting

Installation and connection of confirmed equipment to the client's vessel

Adjustment

The system is tested and, if necessary, refined

Service and Warranty

At the request of the client, the service of the entire system is provided 24/7. We ensure the fulfillment of warranty obligations

5 main solutions

Control automation system - accounting of fuel and vessel efficiency FCM

Monitoring system on board:

- Flow meters for ship consumers

- Hour meters

- Torisometers

- Bunker flow meters

- Load transformers

- GPS units, inclinometer, anemometer, viscometer

- Temperature sensors

- Controllers

- Central computer and other equipment

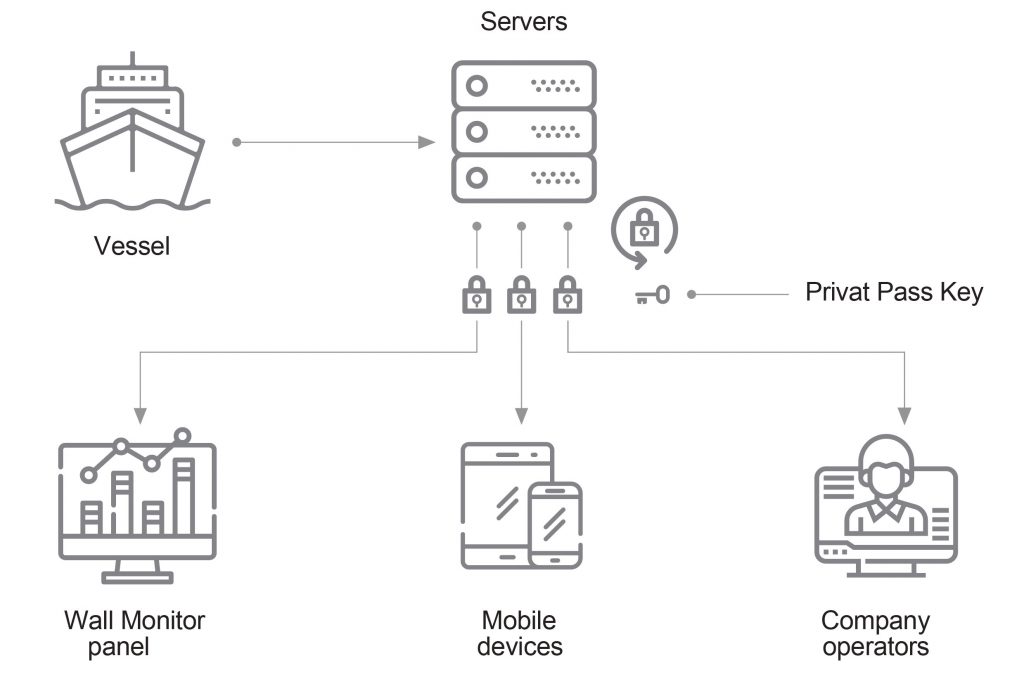

Monitoring and analyzing data in the office:

- User-installed software

- User interface

- Remote access interface (for personal devices)

- Remote access software

- Data management system

Fleet monitoring system

- Software for collecting, processing and analyzing data from the entire fleet

- Comparison of different units of the fleet

- Possibility of issuing recommendations for optimal parameters of work.

- This segment of the system is offered as an option. The cost is calculated separately at the request of the Customer

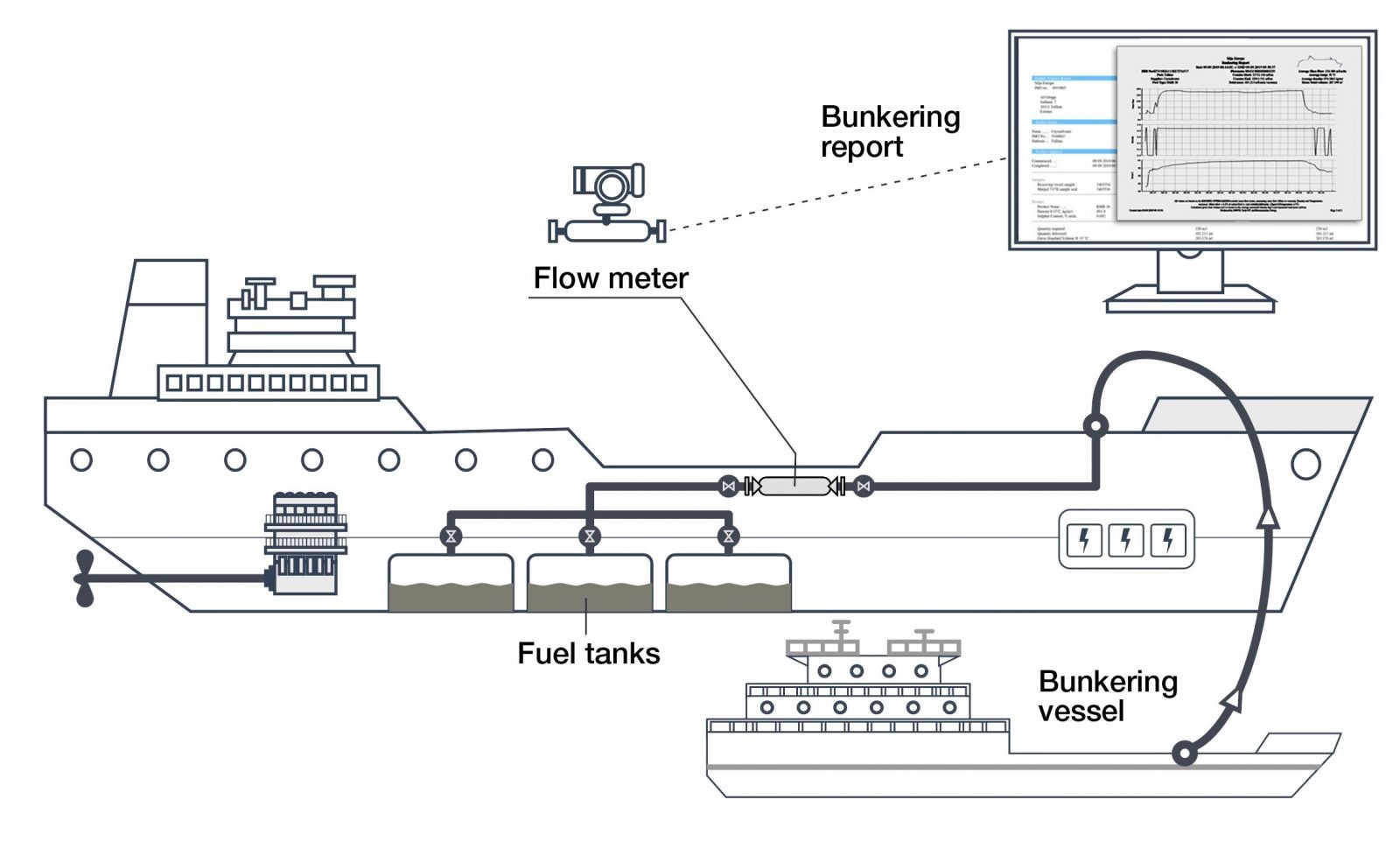

Bunkering / fuel delivery control:

- Custody transfer for bunkering

- Reports in MID and MPA formats in accordance with OIML R117-1 for HFO, MDO and MGO

- Tracking fuel impurities and cappuccino effects

- Measurement accuracy 99.9%

- Measurement of large ducts

- Measurement of volume, density and temperature

- Save time when bunkering at sea

Measurements of levels in tanks:

- Monitoring fuel levels in tanks

- Real-time reports

- Level history

- Alarm limit alarm

- Tracking alarm history

- Measurement of temperature, pressure and density

- High measurement accuracy

- The possibility of combining the system with the operation of additional equipment

- Improved flight planning

- Optimizing speed

- Optimizing shaft power

- Advanced software for calculating fuel consumption

- Analysis of energy consumption, including ventilation and air conditioning systems.

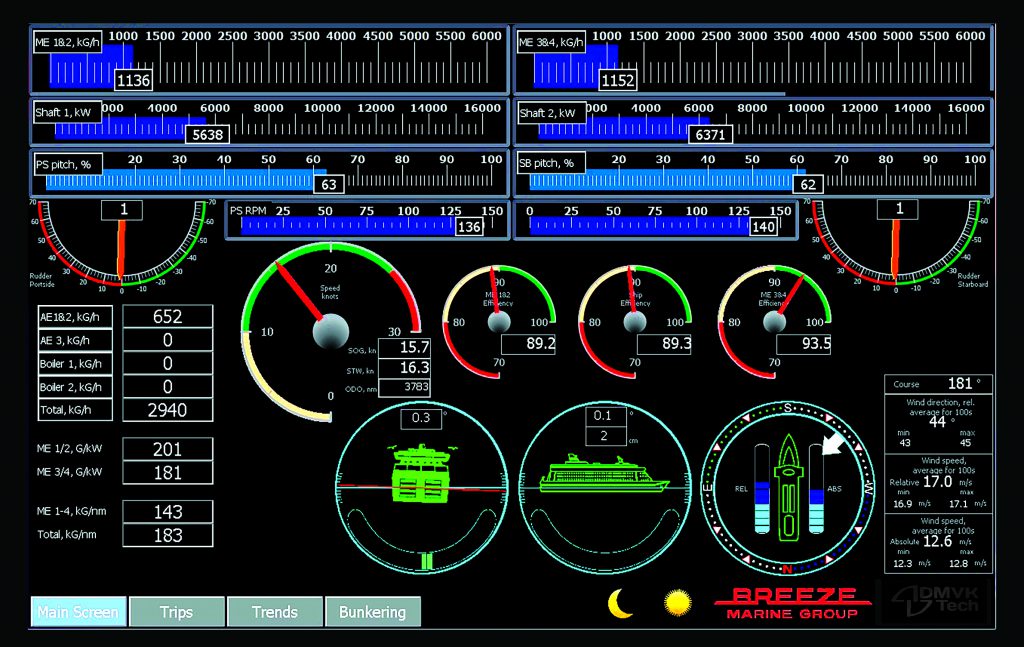

Onboard solutions

Functions, features and benefits of onboard solutions

FEATURES & BENEFITS

Modular system architecture.

Ability to add automation modules.

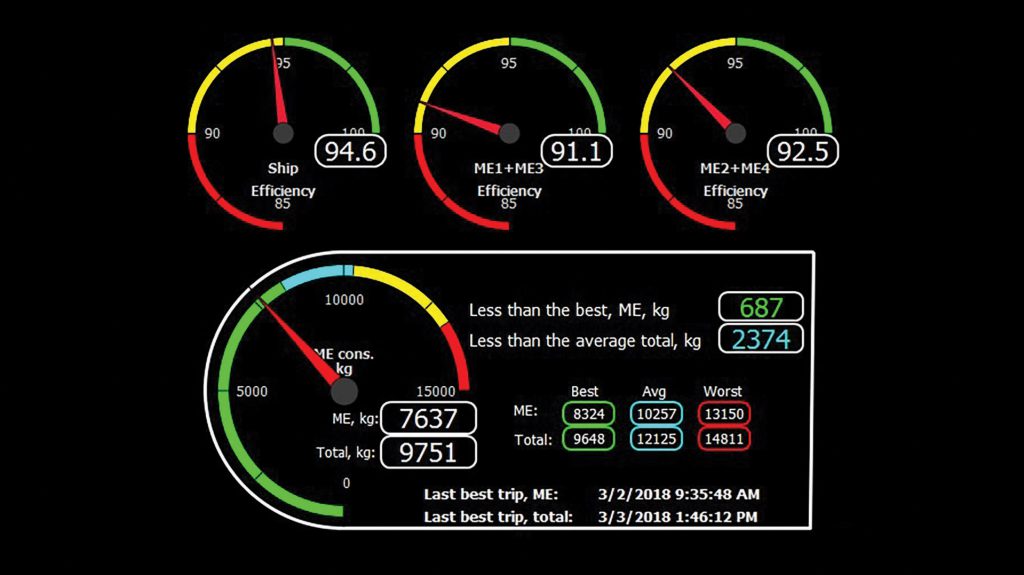

Indicates instant fuel consumption.

High accuracy.

Generation of single and summary reports.

Data for effective, urgent solutions

Convenient data display.

Remote administration capability.

Secure communication through a VPN tunnel.

Flexible interface customization options.

Suitable for LNG fuel systems

CO2 emission report for MRV

FUEL CONSUMPTION CONTROL

Fuel consumption monitoring by each consumer and group

- Real time mode

- Accuracy 0.1%

- History overview

- Data analysis and storage

- Trends overview

- Summary information for the entire flight

- Archiving and exporting data

- And much more

ADDITIONAL OPTIONS

Connecting additional modules to optimize fuel consumption

- GPS module. Current position and distance traveled

- Propeller Shaft Torsiometers (Power / Fuel Consumption)

- Load transformers on VDG

- Navigation and route optimization

- Hydrometeorology

- TRIM module ship draft optimization

- Rudder position sensor

- Blade turn sensor

- Connection to the ship automation control system

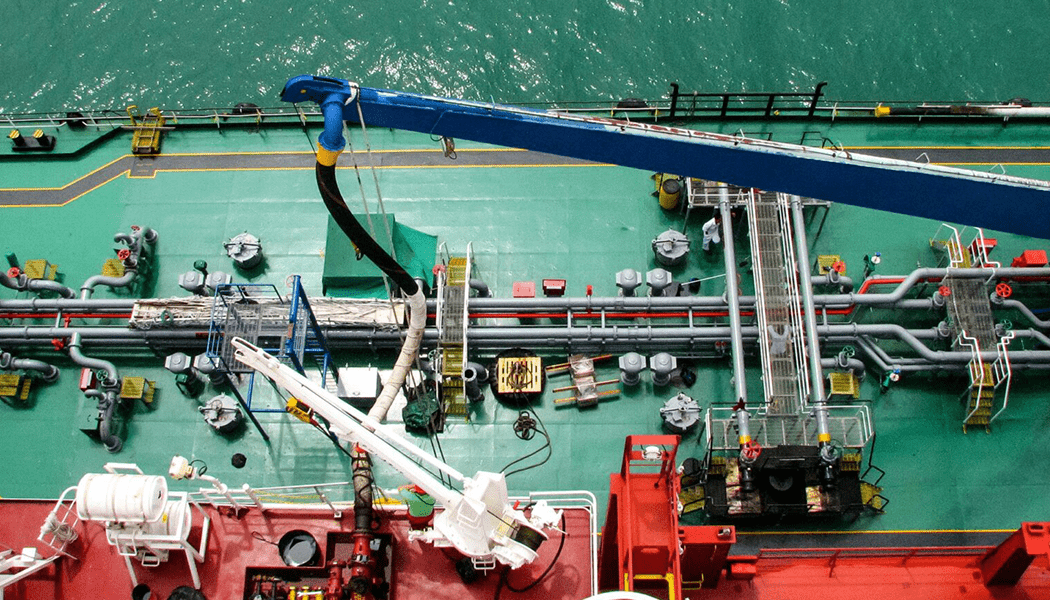

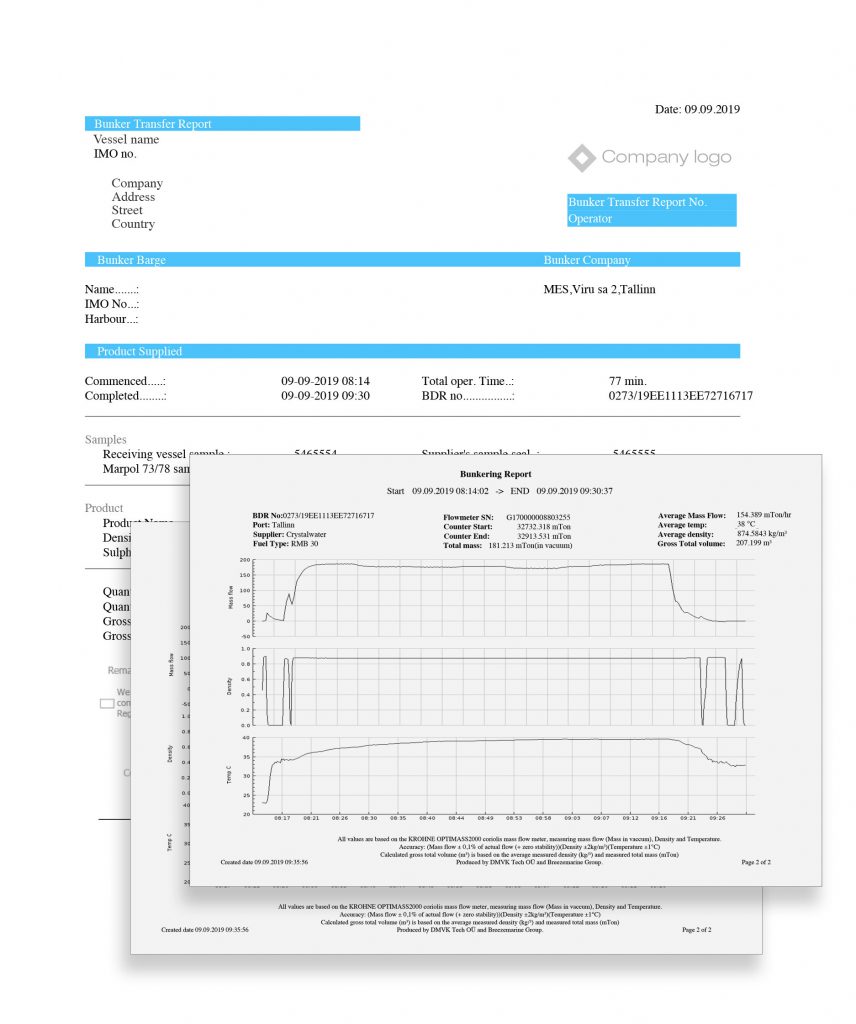

BUNKERING

Bunkering and loading monitoring

- Control over the amount of received fuel

- History overview

- Accuracy 0.5%

- Connection to a common FCM system

- Data analysis and storage

- Archiving and exporting data

- Trend overview

- Bunkering ticket printout

- Control over the quality of the received product in real time

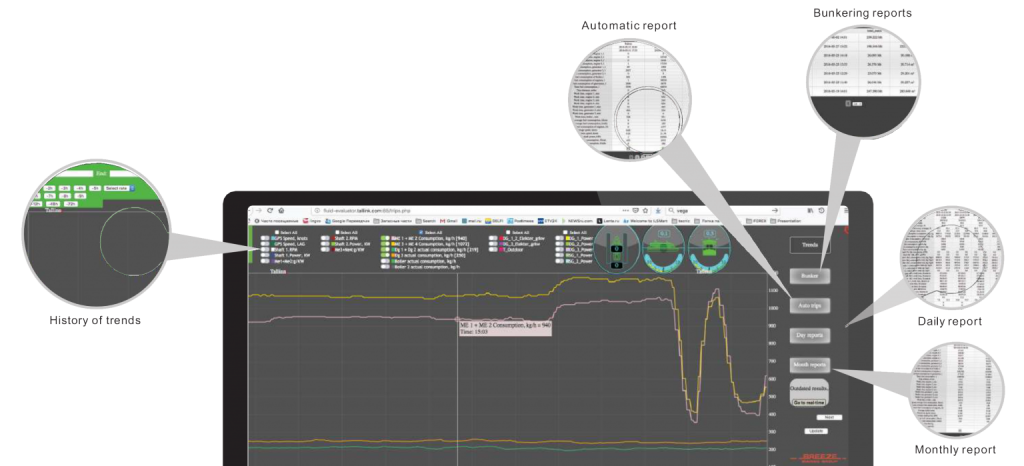

Monitoring system in the office

Features and Benefits of Management Solutions

The office solution is intended for use by operators / superintendents directly in the office or on a personal device (s);

The office system is a VEB-interface that allows you to communicate to request / receive data both with the ship’s server and with the office server, which duplicates and stores all information received from the ship in real time;

A handy tool for daily review and analysis of the set parameters.

A user-friendly and intuitive interface allows you to effectively display various system data.

Flexible possibilities to provide visualisation according to client’s requests.

- Daily reporting

- Monthly reporting

- History of trends

- Automatic reporting

- Bunkering reporting

Fleet solution

Independent module of the fuel metering system on board

Fleet monitoring system solution is:

- A software solution that allows you to control the work of the entire fleet of the Shipowner.

- A software interface that allows users with special clearance to compare the performance of ships using a convenient graphical comparison form, on which it is possible to display all or some of the data from the system for each ship or group of ships.

- A handy tool for day-to-day monitoring of fleet performance and monitoring / analysis of data for a specific vessel or group of vessels.

Fleet performance monitoring and analysis

- Comparison of 2+ vessels or 2+ operating modes of one vessel for any period of time.

- Individual development.

- Personalized interface.

- Advanced vessel monitoring capabilities.

- Multilevel database access system.

- 100% privacy and data protection. WITHOUT CLOUD.

- Indication of the parameters of the best transitions and modes of operation.

- Generation of summary performance reports for the vessel / fleet.

- Flexible options for updating and revision.

Fuel receiving / dispensing control system

Independent module of the fuel metering system on board

An independent module of the fuel metering system on board the vessel, which can be installed both as part of the SKT and separately;

An individually created system for each project using high-precision Coriolis flow meters, controllers and a computer complex.

Visualization of bunkering values and parameters on independent monitors or on existing monitors of other ship systems.

Possibility to integrate the system with the general ship automation system or make it completely autonomous.

- Continuous monitoring of mass, density and temperature in real time.

- Generating bunkering reports

- Operation history up to 5 years

- Convenient data display

- High reliability

- Remote administration capability

- Full automation of the process

- Can be used for LNG systems