Port Stenders

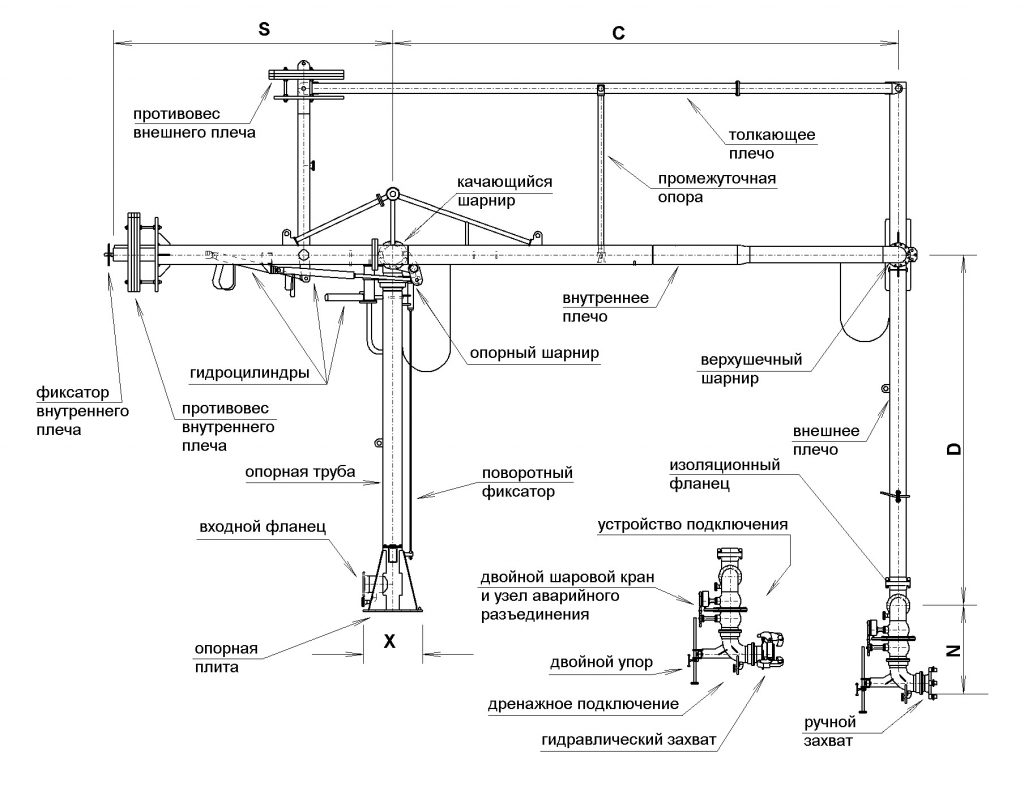

Thanks to the rigid mechanical pantograph system, two separate counterweights on the outer and inner arms provide the arm with full balance. The self-supporting design of the loader offers the optimum solution in terms of safety, light weight and wind loads. Due to that, both the forces necessary for its movement and the load on the foundation are reduced to a minimum.

Loading arm can be produced:

In case of deviations in requirements, we offer an individual solution

Sizes from D 100 mm to D 400 mm

Pressure rates from10 bar to 40 bar

Carbon steel, low temperature steel, stainless steel

For all types of products

Temperature range from -50 °C to +200 °C

Customized solution on request

It is possible to equip with additional equipment:

- envelope warning system

- drainage connections

- emergency release system (ERS) -hydraulic operation

- hydraulic quick coupler

- insulation flange

- manual quick coupler

- nitrogen purge line

- purge line

- vacuum breaker

- vapor return line

To remove off-gases (steam-air mixture, off-gases), a two-pipe loading arm with a product pipeline and an exhaust gas line can be made. If simultaneous loading of two products or one type of product is provided, but it is required to increase the throughput, the loading arm can be equipped with two product pipelines.

Stender equipment Eminent

Loading arms can be produced

With a nominal diameter of the pipeline from 100 to 600 mm.