Ballast Water Treatment Plant (BWTS)

BWTS

BALLAST WATER treatment systems

Very little time is left before a complete ban on the operation of ships without ballast water treatment systems. The International Maritime Organization gave enough time and set a deadline

September 24, 2024.

The advantages of our BWTS systems:

Environmental friendliness

Environmentally friendly. No active substances or chemicals are required for ballast water treatment.

Attention to quality

The installation is made from reliable and well-proven components in marine practice, which ensures safe operation and low operating costs for our customers in the future.

Profitability

It is provided with automatic regulation of power consumption depending on water quality, and UV lamps have a long service life.

Convenience

Intuitive, easy to operate and maintain. The BWT system is connected to the ship's automation and is controlled from the CPU.

Service and spare parts

Maintenance of systems and supply of spare parts is provided throughout the entire period of operation.

Standardization

Our systems are approved according to DNV-GL, IMO and USCG AMS, BUREAU VERITAS and LLOYD'S REGISTER standards.

Ships built after September 8, 2017 are required to comply with the IMO ballast water treatment requirements, while existing ships must have a ballast water treatment system installed by September 24, 2024. In addition, all ships must already have an approved ballast management plan.

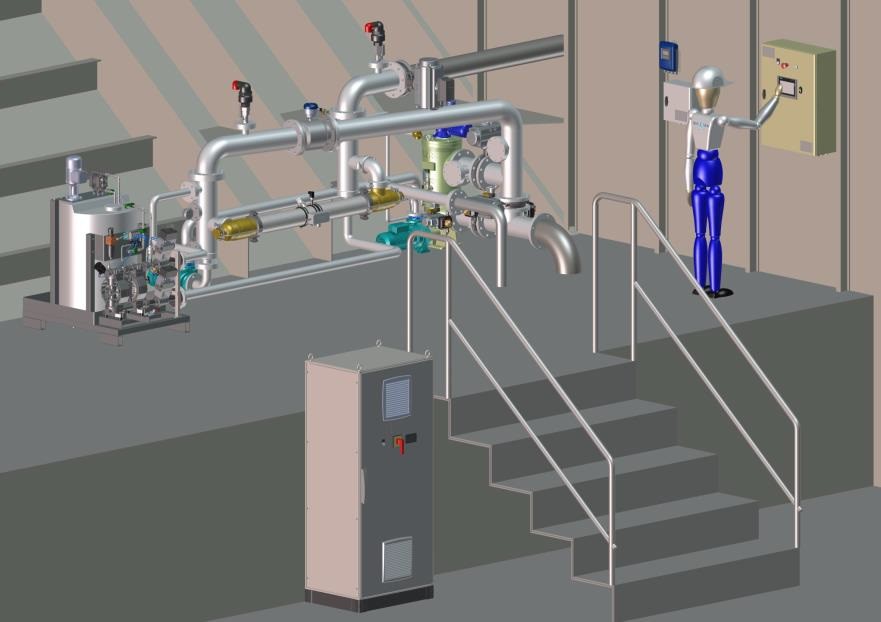

Breezemarine Group - offers shipowners solutions for the installation of ballast water treatment systems based on mechanical filtration and ultraviolet radiation. We design, supply, install and service the smallest energy efficient units on the market for small and medium vessels that meet internationally accepted standards. Together with our partner Norwegian Green Tech, we will select the best installation option for your vessel. We will carry out an inspection on board, design and organize the installation and start-up of the system.

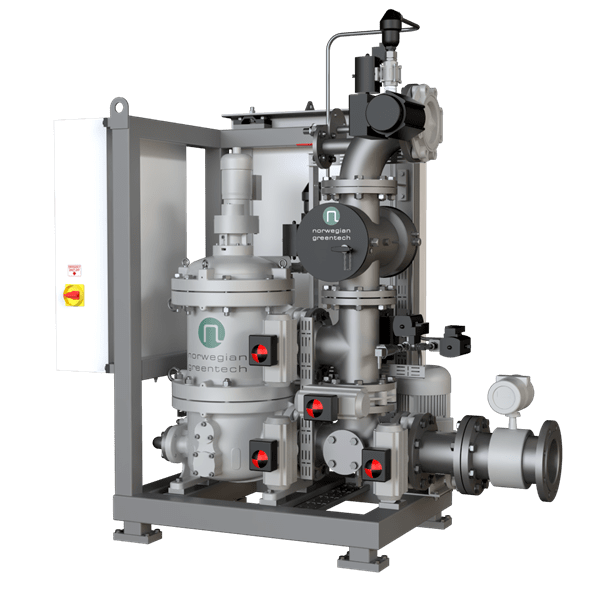

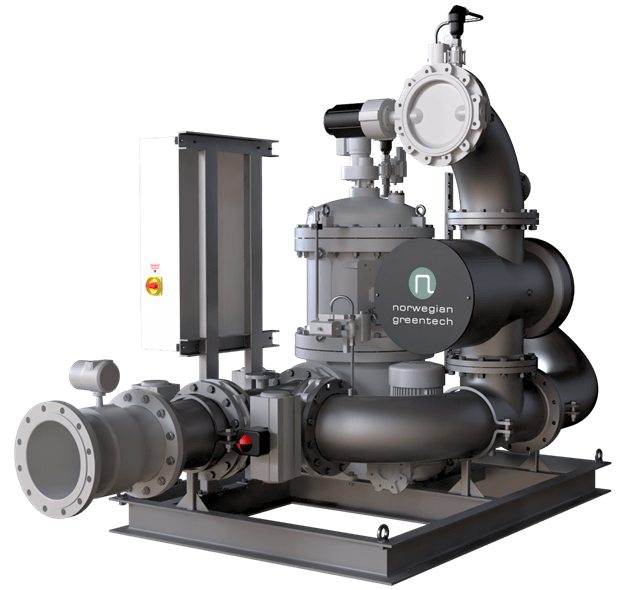

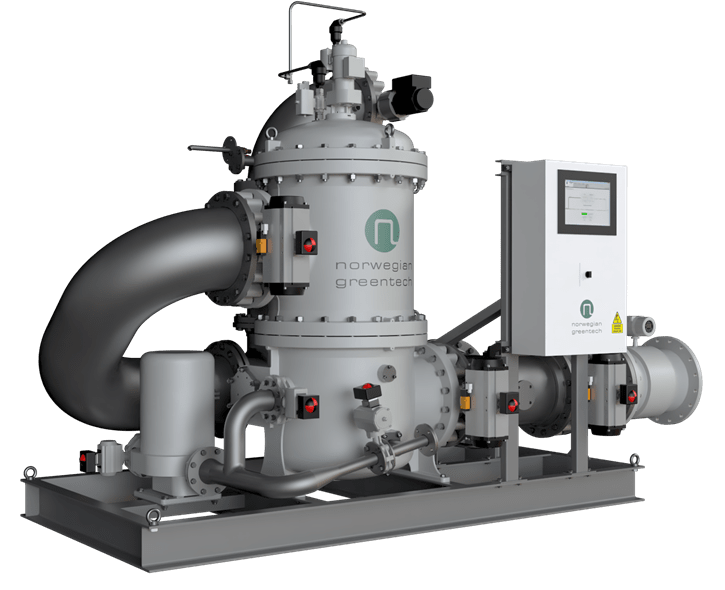

The unique features of the system, along with automatic UV dose control, provide superior energy performance, low life cycle costs and ease of maintenance. The system is environmentally friendly and compact, therefore it is ideal for hard-to-reach places in engine rooms and pump rooms. High quality BWMS Norwegian Greentech is built to last. Fast return on investment.

Our solutions combine the smallest footprint with low energy consumption, installation flexibility and intuitive operation.

Modular / Benefits – Scalable to any flow rate from 10 to 2000 m3 / h (also expandable on request) Flexible footprint

The modular version is an excellent upgrade solution. Electrical and hydraulic connections are simple, optimized and easy to connect to ship systems.

The BWMS version on the frame is a good solution for a new building!

Productivity from 10 to 2000 m3 / h.

All components (filter, UV reactor, etc.) are mounted on the platform. The control cabinet is also platform-mounted. Power cabinets are usually field-installed (but can be platform-mounted along with other components upon request).

Contact us for advice, send inquiries and order the BWTS system from us

We have designed our system based on the markets needs, and as a result have one of the most compact system with the lowest power consumptions on the market today.

Environmental: No active substances required for the treatment process.

Quality: Built of reliable and well proven components, providing our customer with operation security and low operation costs in the future.

User friendly: Our system is both easy to operate and maintain.

System TRC: 50 m3/h

- Flow ballasting: 29-50 m3/h

- Flow de-ballasting: 10-50 m3/h

- Power consumption UV: 2,64 KW - 4,4KW

- Max Power consumption system: 7,6KW

- Skid footprint: 840mm x 670mm (L x W)

- Total height: 1711 mm

System can also be delivered as semi-skid on a bottom frame, with loose cabinets.

System can be delivered in separate components, relevant for retrofit.

System TRC: 100 m3/h

- Flow ballasting: 29-100 m3/h

- Flow de-ballasting: 10-100 m3/h

- Power consumption UV: 5,28 KW - 8,8KW

- Max Power consumption system: 12KW

- Skid footprint: 1119 mm x 800 mm (L x W)

- Total height: 2017 mm

System can also be delivered as semi-skid on a bottom frame, with loose cabinets.

System can be delivered in separate components, relevant for retrofit.

Environmental: No active substances required for the treatment process.

Quality: Built of reliable and well proven components, providing our customer with operation security and low operation costs in the future.

User friendly: Our system is both easy to operate and maintain.

BWMS 150 m3/h

BWMS 300 m3/h

BWMS 500 m3/h

System TRC: 600 m3/h

- Flow ballasting: 93-600 m3/h

- Flow de-ballasting: 20-600 m3/h

- Power consumption UV: 30,24 KW - 50,4 KW

- Max Power consumption system: 60,1KW

- Skid footprint: 2170 mm x 1570 mm (L x W)

- Total height: 2426 mm

System can also be delivered as semi-skid on a bottom frame, with loose cabinets.

System can be delivered in separate components, relevant for retrofit.

Environmental: No active substances required for the treatment process.

Quality: Built of reliable and well proven components, providing our customer with operation security and low operation costs in the future.

User friendly: Our system is both easy to operate and maintain.

BWMS 750 m3/h

BWMS 1000 m3/h

Environmental: No active substances required for the treatment process.

Quality: Built of reliable and well proven components, providing our customer with operation security and low operation costs in the future.

User friendly: Our system is both easy to operate and maintain.

System TRC: 1200 m3/h

- Flow ballasting: 155-1200 m3/h

- Flow de-ballasting: 20-1200 m3/h

- Power consumption UV: 60,48 KW - 100,8 KW

- Max Power consumption system: 116,8 KW

- Skid footprint: 3130 mm x 1580 mm (L x W)

- Total height: 2886 mm